Its early January, and you know what that means: New Years resolutions. The vast majority of those will seem to be fitness related, so today we will look at how 3D printing has affected the athletics industry.

In keeping with the season, 3D printing has made a scene at last years’ Winter Paralympics, which makes sense considering the need for custom gear. Biathlete Martin Felig used 3D printed ski’s for the Winter games in Sochi:

The first prototype (of the ski’s for German biathlete Martin Felig) was manufactured using polyamide 12 high-performance polymer and fitted with sensors to measure stresses occurring during use. Through the data collected, the Fraunhofer scientists developed a second prototype (by simply modifying the digital model and “sintering out” a new physical model). This second reinforced model was then tried and pushed to its limits by Fleig at the at the Notschrei Nordic Center in Germany’s Black Forest and at the altitude training camp in Livigno, Italy. 3D Printed Sit Skis at the Winter Paralympics - 3D Printing Industry

Nike has also gotten in on the idea of using 3D printing for large international sporting events, having designed 3D printed soccer bags for the 2014 World Cup.

The brand claims that the Nike Football Rebento duffle bag is the first world’s first 3D-printed football bag. It has been designed as a sports equipment holder for football players at the 2014 World Cup.

Nike 3D-printed the mesh covering of the bag using laser-sintered nylon, in a pattern referencing the stud plate on the bottom of their Flyknit boots.

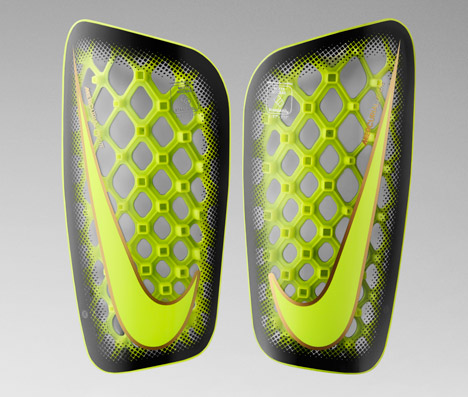

Alongside the duffel bag, the players will be given 3D-printed shin guards designed to be aerodynamically enhanced. Nike launches 3D-printed sports bag for Brazil 2014 World Cup

Other big brands have gotten in on the 3D printing revolution, including HEAD, a tennis racket manufacturer:

HEAD just released its Adaptive String Pattern (ASP) technology which is a system based on two exchangeable grommet sets that can be selected to achieve more spin and power or, alternatively, for more control. Although it does allow for a higher degree of personalization – at least in terms of performance – the final product does not require to be 3D printed, however the original prototype was, as Schwinger revealed that HEAD has been an adopter of 3D printing technologies since 2002. HEAD Sports & 3D Printing - 3D Printing Industry

Ralf Schwinger, R&D Director for HEAD Sports, did note that while there are many real-world applications of 3D printing for the sporting industry, there is also a lot of hype about current consumer applications, which are still somewhat down the road.

Mr Schwinger stressed that although many things are possible (such as Local Motors’ 3D printed cars) it does not mean they are feasible on a mass market scale and that sometimes 3D printing lets creative minds dive into “wishful designs” that are not necessarily efficient or attractive to the end user (3DPI’s coverage of the CRP futuristic tennis racquet was expressly mentioned as an example).

The racket in question?

Thanks to 3D printing, this futuristic concept did not remain confined to the computer screen but it was actually produced. The prototype was designed by separating the racket into it main parts: the neck, throat and head, studying each one for structural variants that would not affect the homogeneity of the whole body and the balance between the different components. 3D Printed Tennis Racket by CRP - 3D Printing Industry

As a runner, I know the difference that a shoe can make on performance. 3D printing, which allows for high-levels of customization, is offering high-level athletes the chance to customize their shoe to their foot and stride:

Contracted New Balance athlete Jack Bolas ran a 4.01.44 indoor mile recently in what may be his most talked about performance to date. The reason being, he was the first ever athlete to be wearing 3D printed equipment specially formulated for his feet and performance levels. Sportwear giant Nike were first to announce their first printed shoes back in February with their Nike Lasor Venim Talon shoe that has similar design aesthetics in mind; to aid athletes’ traction during performance. Yet New Balance were first to have an athlete physically compete in a race, bringing further attention to what could be the future of performancewear. New Balance 3D Printed Shoes Can Run In Races - PSFK

The NBA is also getting in on the 3D printing craze, with the Kings looking into potential 3D printing applications for their franchise.

The team did not share specifics, but Senior VP/Strategy, Innovation & Technology Ryan Montoya in an e-mail wrote team execs “hope to implement 3D printing usage throughout our organization.” This development comes after the team last season held a tech event featuring 3D-printer demonstrations.

The club currently has made no firm commitment to testing the technology, but VP/Digital & Marketing Kenny Lauer said that ownership is supportive of the idea and utilizing the printers at some point in the near future is likely. NBA Kings Among First Pro Teams To Begin Experimenting With 3D Printing Technology - SportsBusiness Daily | SportsBusiness Journal | SportsBusiness Daily Global

I personally am looking forward to the continued advancements made for 3D printing athletic gear.